Wolfmother

Race Dog

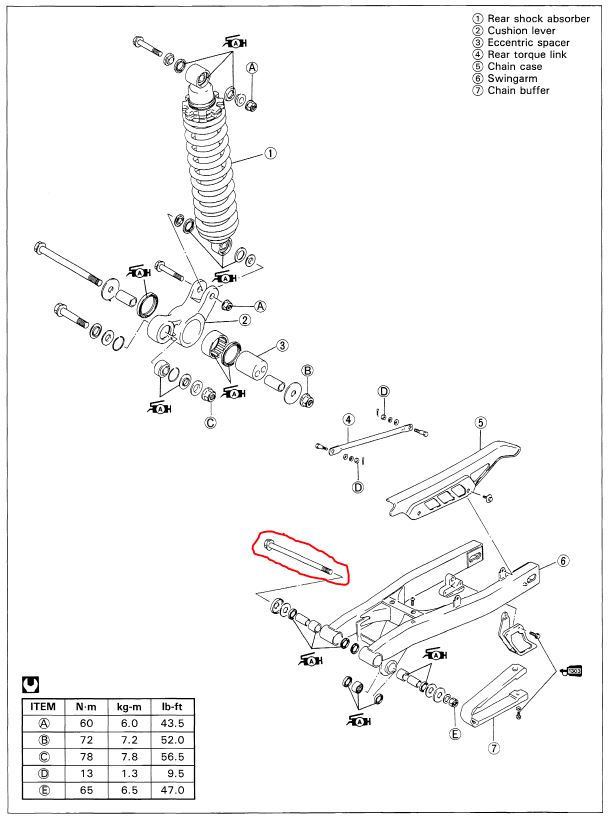

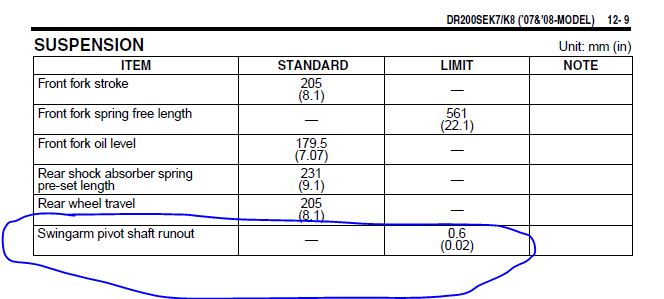

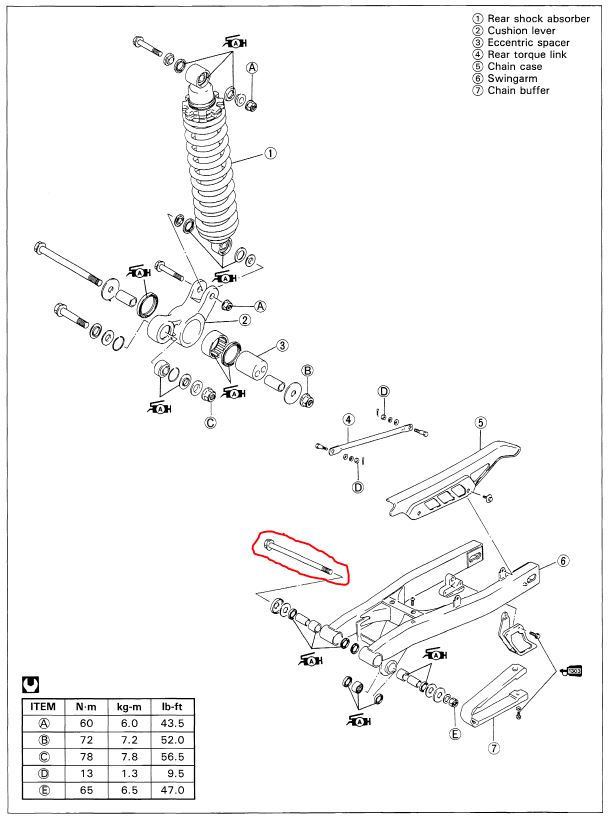

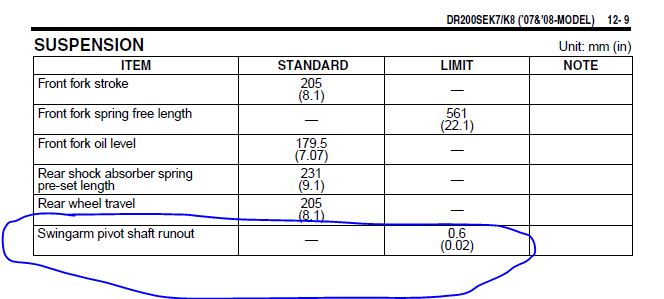

I had to saw off the head of the swingarm pivot bolt to get it out. Where can I get one here in Cape Town? The old one is still in a condition that I can measure it up to be machined but I would prefer to get one from somewhere.