Vintage_Mania

1979 Honda CB400T

*from MCNews.com.au

The 500cc class of the World Road Race Championships, which was competed on two-stroke machines until 2001, became a mixed two- and four-stroke competition in 2002 with the start of the new MotoGP regulation. And, as of the 2003 season, the MotoGP class has become in effect a completely four-stroke competition, thus bringing to a close the age of the two-stroke 500cc machines. Many dramas unfolded during Yamaha’s three decades of GP500 class racing, a period which saw Yamaha engineers involved in the ongoing challenge of expanding the potential of the two-stroke engine.

The Yamaha YZR500 factory machine won its World GP debut race back in April 1973 at the French GP, breaking the domination of the MV Agusta machines. And, after winning the manufacturers championship the following year, 1974, Yamaha continued to compete in GP racing for thirty years with its evolving YZR500 factory machines. During this period the YZR500 chalked up an enviable record of 115 wins at the hands of 20 different riders while winning a total of 11 rider championship titles and nine manufacturers titles.

The history of the YZR500 is also a history of technological innovation and evolution. In countless technologies from the YPVS born of environmental measures, the rear-exhaust system, the Deltabox frame that contributed to the machine’s outstanding handling characteristics and the electronic-control suspension to the release of technologies for the YZR500 machine itself, can be found a history of Yamaha’s philosophy of technological development. In this record of the YZR500 and its history, we look at the qualities of the successive models based on the words of the Yamaha engineers who worked on their development.

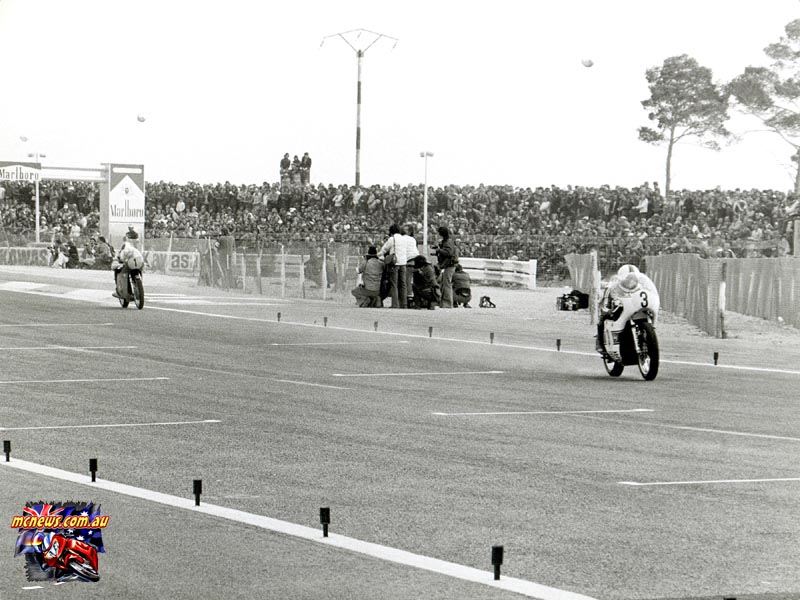

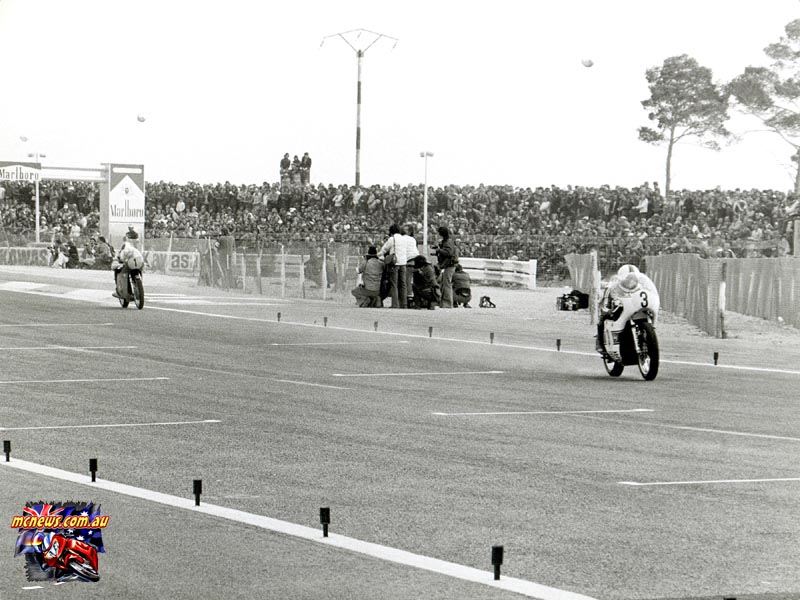

The date was April 22, 1973, and the place was the opening round of the GP series at the Paul Ricard circuit in France. For Yamaha this race marked its first GP challenge in five years and its first ever in the 500cc class. The riders who would mount the new Yamaha machine that had been developed under the OW20 code name were the previous year’s 250cc class champion on a TZ250 Yamaha prototype Jarno Saarinen of Finland and Japan’s Hideo Kanaya.

That day, Saarinen would ride the first YZR500 to victory over the 20-lap, 116.2 km course in a time of 45 min. 57 sec. to beat rival Phil Read on the MV Agusta four-stroke machine by a full 16-second margin. Kanaya followed in third place. In the second round of the series at the rainy Saltzburg circuit in Germany, Saarinen and Kanaya would finish one-two, and in doing so herald the start of a new era in GP racing.

It was the start of a new era in that the strength of the two-stroke Yamaha machine ended the domination of the four-stroke MV Agusta in the GP500 class. At the time, some 20 different makes of 500cc machines were competing in the class, including two-stroke machines from Harley-Davidson, Husqvarna, Konig, Ducati, Bultaco, Norton, BMW and Triumph, but none could stop the winning streak of the four-stroke MV Agusta.

With the exception of one win by Honda in 1966, Agusta had won the manufacturers title every year since 1958. The two-stroke models just couldn’t keep up and it was an era when there was not even a thought of the possibility of holding a round of the world championship in Japan. Nonetheless, Yamaha was working diligently on the challenge of developing the potential of the two-stroke engine.

Still, the OW20 prototype was not the product of a development project aimed solely at the GP500 class. At that time, in the latter half of the 1960s, Yamaha was looking at the U.S. market as one with big potential and since 1968 had been competing in America’s biggest motorcycle race event, the Daytona 200. At that time the Yamaha race machine was based on the 350cc TR2, but as rival makers began introducing 750cc machines Yamaha began developing a liquid-cooled in-line four-cylinder 700cc two-stroke machine dubbed the YZ648 from May of 1971.

For the power unit, a “V” type engine had been an option, but taking into consideration the race competitiveness and reliability, the Yamaha engineers had decided to go with an in-line four-cylinder configuration that basically lined up two of the 350cc TR2 racer’s engines in one block. At the same time, development work was begun on the 500cc OW20 prototype that would eventually become the ’73 YZR500. Due to the regulation requiring that 700cc class machines for the Daytona race be production machines manufactured in a lot of at least 200 units, the YZ648 adopted a die-cast crank case. In contrast, the OW20 was built with a sand-cast crankcase.

Retired Yamaha engineer Takashi Matsui recalls the start of the development project: “We were intending to eventually participate in the GP500 class so we started work on a 500cc model, but at the same time we had our eyes on Daytona. So we started developing a 700cc models simultaneously, calling the 700cc the “YZ648″ and the 500cc the “YZ648A.” By October of 1971 we had completed three prototypes to the point where they were running fairly well. Then we spent all of 1972 developing the finer details of the machines, which were now being referred to by their development code names “OW19″ (700cc) and “OW20″ (500cc).”

A number of innovative features were developed during that year. “In order to get a much slimmer engine design, we grouped the four cylinders into units of two each and then introduced an “idle shaft” between the right and left crank shafts as the drive force shaft. The enabled an engine width about the same as a V-4. And to make the overall design even more compact, we fitted the ignition system in the space on the non-drive end of the idle shaft axis,” adds Mr. Matsui.

“From our experience developing the RD05 (the 1964 250cc GP machine) we learned that the ignition order has a big effect on the idle gear, and so we decided to use a well-balanced firing order in which the two inside cylinders and the two outside cylinders fired at the same time. In our efforts to increase the machine’s potential banking angle, we designed triangular cross-section mufflers and grouped all four exhaust pipes together and ran them under the crank cases,” recalls Mr. Matsui. These models also adopted a new chromium molybdenum steel frame with a wide-type side rail and disc brakes were added front and rear.

“At the time, we were told that the three-cylinder engines of the rival makers put out about 102 hp, while our OW20 put out 95 hp. So, the reason we were able to win our debut race was surely a result of the machine’s good overall balance rather than its acceleration,” concludes Masakazu Shiohara, head of the testing team at the time. As we see, the Yamaha development philosophy of pursuing overall performance and handling rather than depending simply on power output was already present from the first YZR500. Yamaha’s commitment to racing was also made evident the following year, 1974, when a contract was signed with Italian hero and greatest GP rider of the day, Giacomo Agostini.

The machine that Johnny Cecotto rode to victory in the Finnish GP in July of 1977 mounted a secret new device. The machine’s development name was the OW35K and it was the first YZR500 to mount what would come to be known as the Yamaha Power Valve System (YPVS). In February of the next year, 1978, when Yamaha announced its GP race program for the year, it also officially introduced its YPVS technology. The YZR500 mounting the new YPVS would be ridden that season in the 500cc class by Kenny Roberts and Cecotto, who had also been competing in the new World Championships Formula 750 class since 1977 on the YZR750 without YPVS.

At the time, the GP500 class was dominated by the Suzuki RG500, while the Formula 750 class was dominated by Yamaha bikes (three straight titles form 77-79). The YPVS technology on the new Yamaha 500cc machines quickly won attention, however, because it clearly gave them a major advantage over the rival machines in the Grand Prix.

The roots of the YPVS technology actually went back three years to know-how developed for emissions measures in 1974. Since the new device also improved performance, it was first applied in racing on Yamaha’s motocrossers and then on road racers and finally production models.

Compared to a normal four-stroke, a two-stroke only emits about 1/10th the amount of NOx, but due to the blow-by phenomenon, the two-stroke emits larger amounts of HC. Reducing these HC emissions was the development theme. Efforts to increase two-stroke power output by speeding up the exhaust timing and using the exhaust interference wave to force gas into the combustion chamber proved successful in the desired high-speed range but also resulted in an increase in blow-by gas in the low speed range, thus creating an emissions problem. It also caused a torque valley that was undesirable on a performance race machine. In order to solve this problem, a valve that enabled variable exhaust timing was added. Operating in accordance with engine rpm, this YPVS device made it possible to optimize exhaust timing at each speed range.

The exhaust pattern on a two-stroke engine is a cyclical one that corresponds to the combustion in the cylinders, and there are certain rpm zones where the pressure in the exhaust pipes is subject to either a cancelling out or augmentation of the pulse due to the overlapping of the successive exhausts. When negative pressure resulting from the mutual cancelling out of pulses occurs in the area of the exhaust pipe at the moment of exhaust, it increases exhaust efficiency and thus engine performance. “The history of trying to improve this unique two-stroke characteristic, called the Kadenacy effect, is virtually the history to two-stroke engine development itself. And, in the long history of Yamaha’s development of the YZR500, no single improvement has led to a bigger improvement in its lap times at the Yamaha test course than the adoption of YPVS,” says Mr. Shiohara.

Looking at the YZR500’s performance figures over the years we see that horsepower climbed from 80PS for the first model (1973) to 180PS for the 1996 model, while the maximum rpm climbed from 10,000 for the first model to 12,500 for the 2002 model. Clearly the rise in power output has been much greater than that in rpm, and the reason for this is largely the results of Yamaha engineers’ efforts to improve the “Kadenacy effect” through measures like the YPVS.

Bringing the YPVS to competition models actually involved a lot of trial and error. “The decision was made to introduce the YPVS device in GP road racing from March of 1977 and the machine chosen to mount it on was the ’77 GP machine OW35. It was given a new project code, OW35K, and work got under way. Development work had already been done for mounting the system on single-cylinder motocrossers, but this was the first time for a four-cylinder machine, and it brought a number of unique problems, like how to attach the cylinder to the crankcase and whether to make the four YPVS valves jointly operable,” says Mr. Taichi Ito, one of the engineer staff.

“The most common way to fasten the cylinder to the crankcase was to use stud bolts and nuts to bolt it down together with the cylinder head. However, due to the addition of the drum-shaped YPVS valves to the cylinders, a normal through-type stud bolt could not be used on the front side of the cylinder. So, at first we adopted a system where a flange was added to the front side or the cylinder for fastening, while the rear side was fastened in the usual method along with the cylinder head with stud bolts and nuts. But, the fact that the front and rear sides of the cylinders were fastened differently, thus creating imbalances in load, led to problems like cracking of the cylinders or crankcases. So, eventually we had to use a flange system on the rear side as well,” recalls Mr. Ito.

“What’s more, the addition of the YPVS valve caused greater heat distortion in the cylinders that led to problems like piston seizure, so we had to try a lot of new methods to alleviate this problem, like changing the shape to the piston cam model and the honing of the cylinder,” adds Mr. Ito. But these development efforts paid off, and eventually contributed to Roberts winning his first world title on the YZR500 in 1978. This returned the title to Yamaha after successive wins by Barry Sheene on his Suzuki in ’76 and ’77. As the YPVS continued to evolve, Roberts went on to win three successive titles.

Today, a wide range of two-stroke powered Yamaha products from production Enduro and motocross machines to production road racers, snowmobiles and personal watercraft mount the YPVS technology. Among these, Yamaha’s Wave Runner PWCs use the YPVS as a device to boost the effectiveness of the exhaust-cleaning catalyzer by functioning to control exhaust temperature. This technological know-how would play a vital roll in the YZR500s revolution after the OW35K.

In 1981, the year after Kenny Roberts won his third consecutive world title on the YZR500, the GP became the focus of attention for new reasons. That year, Yamaha introduced a square-four model YZR500 (OW54), while Suzuki introduced the RGG500 with a square-four with a level difference between the two front and two rear cylinders. Kawasaki rolled out its KR500 and Honda entered with the four-stroke NR500. The next year, Honda finally came in with the two-stroke, three-cylinder NS500. As it turned out, the winners in ’81 and ’82 were Suzuki’s Marco Lucchinelli and Franco Uncini.

Amid these developments, Yamaha introduced its last parallel four (OW53) and its first square-four (OW54) in 1981. In 1984 came the second-generation Yamaha square-four (OW60) and its first V4 engine model, the OW61. “Through 1980 we ran with the parallel fours, but in order to match the power performance of the rival square-fours, we began development of a V4 as our next-generation racer. There was a lot of risk involved in suddenly jumping in to the races with a V4, so we first developed the same kind of square-four as the competition and fed back used the race data gained with it to the V-4 development project,” recalls Mr. Ito. What proved to be the biggest problem with the V4 design, however, was the layout of the intake system.

The square-four model OW54 introduced in 1981 adopted a rotary-disc valve that definitely delivered more power than the conventional piston-valve type parallel four. However, the added weight of the engine affected the handling stability, which led to a number of problems. Eventually, the V4 engine OW61 model was the product of development efforts aimed primarily at solving these problems by reducing engine weight and reducing its width to one comparable to a 250cc engine.

Since a two-stroke engine has a separate crankcase for each cylinder, the width of a single-axis (shaft) V4 ends up being about the same with as a parallel four. However, adopting a two-axis design enabled a design with less right-left width. It also theoretically offered the advantage of easier voluntary adjustment of the ignition angle, but the problem became where to position the intake system. In other words, the question was where on a V-4 design could you position the intake system for the rotary disc that was normally positioned on the side (lateral) surface of the cylinder.

The key that would lead to the solution of this problem came from words muttered by one of the engineers in a development staff meeting. “One day, one of our engineers was mumbling to himself, ‘If only the disc could within the “V” bank between the cylinders.’ At that minute the whole picture became clear,” recalls Mr. Shiohara. This gave birth to a highly original concept of throwing out the side-mounted rotary disc with its inherently limited forward projection area, positioning the carburettors in the “V” of the block and having one rotary disc service two cylinders. Now the race was on to test a prototype and get it ready for use in actual competition. This led to the birth of the rear-surface rotary-disc valve intake system.

The 500cc class of the World Road Race Championships, which was competed on two-stroke machines until 2001, became a mixed two- and four-stroke competition in 2002 with the start of the new MotoGP regulation. And, as of the 2003 season, the MotoGP class has become in effect a completely four-stroke competition, thus bringing to a close the age of the two-stroke 500cc machines. Many dramas unfolded during Yamaha’s three decades of GP500 class racing, a period which saw Yamaha engineers involved in the ongoing challenge of expanding the potential of the two-stroke engine.

The Yamaha YZR500 factory machine won its World GP debut race back in April 1973 at the French GP, breaking the domination of the MV Agusta machines. And, after winning the manufacturers championship the following year, 1974, Yamaha continued to compete in GP racing for thirty years with its evolving YZR500 factory machines. During this period the YZR500 chalked up an enviable record of 115 wins at the hands of 20 different riders while winning a total of 11 rider championship titles and nine manufacturers titles.

The history of the YZR500 is also a history of technological innovation and evolution. In countless technologies from the YPVS born of environmental measures, the rear-exhaust system, the Deltabox frame that contributed to the machine’s outstanding handling characteristics and the electronic-control suspension to the release of technologies for the YZR500 machine itself, can be found a history of Yamaha’s philosophy of technological development. In this record of the YZR500 and its history, we look at the qualities of the successive models based on the words of the Yamaha engineers who worked on their development.

The date was April 22, 1973, and the place was the opening round of the GP series at the Paul Ricard circuit in France. For Yamaha this race marked its first GP challenge in five years and its first ever in the 500cc class. The riders who would mount the new Yamaha machine that had been developed under the OW20 code name were the previous year’s 250cc class champion on a TZ250 Yamaha prototype Jarno Saarinen of Finland and Japan’s Hideo Kanaya.

That day, Saarinen would ride the first YZR500 to victory over the 20-lap, 116.2 km course in a time of 45 min. 57 sec. to beat rival Phil Read on the MV Agusta four-stroke machine by a full 16-second margin. Kanaya followed in third place. In the second round of the series at the rainy Saltzburg circuit in Germany, Saarinen and Kanaya would finish one-two, and in doing so herald the start of a new era in GP racing.

It was the start of a new era in that the strength of the two-stroke Yamaha machine ended the domination of the four-stroke MV Agusta in the GP500 class. At the time, some 20 different makes of 500cc machines were competing in the class, including two-stroke machines from Harley-Davidson, Husqvarna, Konig, Ducati, Bultaco, Norton, BMW and Triumph, but none could stop the winning streak of the four-stroke MV Agusta.

With the exception of one win by Honda in 1966, Agusta had won the manufacturers title every year since 1958. The two-stroke models just couldn’t keep up and it was an era when there was not even a thought of the possibility of holding a round of the world championship in Japan. Nonetheless, Yamaha was working diligently on the challenge of developing the potential of the two-stroke engine.

Still, the OW20 prototype was not the product of a development project aimed solely at the GP500 class. At that time, in the latter half of the 1960s, Yamaha was looking at the U.S. market as one with big potential and since 1968 had been competing in America’s biggest motorcycle race event, the Daytona 200. At that time the Yamaha race machine was based on the 350cc TR2, but as rival makers began introducing 750cc machines Yamaha began developing a liquid-cooled in-line four-cylinder 700cc two-stroke machine dubbed the YZ648 from May of 1971.

For the power unit, a “V” type engine had been an option, but taking into consideration the race competitiveness and reliability, the Yamaha engineers had decided to go with an in-line four-cylinder configuration that basically lined up two of the 350cc TR2 racer’s engines in one block. At the same time, development work was begun on the 500cc OW20 prototype that would eventually become the ’73 YZR500. Due to the regulation requiring that 700cc class machines for the Daytona race be production machines manufactured in a lot of at least 200 units, the YZ648 adopted a die-cast crank case. In contrast, the OW20 was built with a sand-cast crankcase.

Retired Yamaha engineer Takashi Matsui recalls the start of the development project: “We were intending to eventually participate in the GP500 class so we started work on a 500cc model, but at the same time we had our eyes on Daytona. So we started developing a 700cc models simultaneously, calling the 700cc the “YZ648″ and the 500cc the “YZ648A.” By October of 1971 we had completed three prototypes to the point where they were running fairly well. Then we spent all of 1972 developing the finer details of the machines, which were now being referred to by their development code names “OW19″ (700cc) and “OW20″ (500cc).”

A number of innovative features were developed during that year. “In order to get a much slimmer engine design, we grouped the four cylinders into units of two each and then introduced an “idle shaft” between the right and left crank shafts as the drive force shaft. The enabled an engine width about the same as a V-4. And to make the overall design even more compact, we fitted the ignition system in the space on the non-drive end of the idle shaft axis,” adds Mr. Matsui.

“From our experience developing the RD05 (the 1964 250cc GP machine) we learned that the ignition order has a big effect on the idle gear, and so we decided to use a well-balanced firing order in which the two inside cylinders and the two outside cylinders fired at the same time. In our efforts to increase the machine’s potential banking angle, we designed triangular cross-section mufflers and grouped all four exhaust pipes together and ran them under the crank cases,” recalls Mr. Matsui. These models also adopted a new chromium molybdenum steel frame with a wide-type side rail and disc brakes were added front and rear.

“At the time, we were told that the three-cylinder engines of the rival makers put out about 102 hp, while our OW20 put out 95 hp. So, the reason we were able to win our debut race was surely a result of the machine’s good overall balance rather than its acceleration,” concludes Masakazu Shiohara, head of the testing team at the time. As we see, the Yamaha development philosophy of pursuing overall performance and handling rather than depending simply on power output was already present from the first YZR500. Yamaha’s commitment to racing was also made evident the following year, 1974, when a contract was signed with Italian hero and greatest GP rider of the day, Giacomo Agostini.

The machine that Johnny Cecotto rode to victory in the Finnish GP in July of 1977 mounted a secret new device. The machine’s development name was the OW35K and it was the first YZR500 to mount what would come to be known as the Yamaha Power Valve System (YPVS). In February of the next year, 1978, when Yamaha announced its GP race program for the year, it also officially introduced its YPVS technology. The YZR500 mounting the new YPVS would be ridden that season in the 500cc class by Kenny Roberts and Cecotto, who had also been competing in the new World Championships Formula 750 class since 1977 on the YZR750 without YPVS.

At the time, the GP500 class was dominated by the Suzuki RG500, while the Formula 750 class was dominated by Yamaha bikes (three straight titles form 77-79). The YPVS technology on the new Yamaha 500cc machines quickly won attention, however, because it clearly gave them a major advantage over the rival machines in the Grand Prix.

The roots of the YPVS technology actually went back three years to know-how developed for emissions measures in 1974. Since the new device also improved performance, it was first applied in racing on Yamaha’s motocrossers and then on road racers and finally production models.

Compared to a normal four-stroke, a two-stroke only emits about 1/10th the amount of NOx, but due to the blow-by phenomenon, the two-stroke emits larger amounts of HC. Reducing these HC emissions was the development theme. Efforts to increase two-stroke power output by speeding up the exhaust timing and using the exhaust interference wave to force gas into the combustion chamber proved successful in the desired high-speed range but also resulted in an increase in blow-by gas in the low speed range, thus creating an emissions problem. It also caused a torque valley that was undesirable on a performance race machine. In order to solve this problem, a valve that enabled variable exhaust timing was added. Operating in accordance with engine rpm, this YPVS device made it possible to optimize exhaust timing at each speed range.

The exhaust pattern on a two-stroke engine is a cyclical one that corresponds to the combustion in the cylinders, and there are certain rpm zones where the pressure in the exhaust pipes is subject to either a cancelling out or augmentation of the pulse due to the overlapping of the successive exhausts. When negative pressure resulting from the mutual cancelling out of pulses occurs in the area of the exhaust pipe at the moment of exhaust, it increases exhaust efficiency and thus engine performance. “The history of trying to improve this unique two-stroke characteristic, called the Kadenacy effect, is virtually the history to two-stroke engine development itself. And, in the long history of Yamaha’s development of the YZR500, no single improvement has led to a bigger improvement in its lap times at the Yamaha test course than the adoption of YPVS,” says Mr. Shiohara.

Looking at the YZR500’s performance figures over the years we see that horsepower climbed from 80PS for the first model (1973) to 180PS for the 1996 model, while the maximum rpm climbed from 10,000 for the first model to 12,500 for the 2002 model. Clearly the rise in power output has been much greater than that in rpm, and the reason for this is largely the results of Yamaha engineers’ efforts to improve the “Kadenacy effect” through measures like the YPVS.

Bringing the YPVS to competition models actually involved a lot of trial and error. “The decision was made to introduce the YPVS device in GP road racing from March of 1977 and the machine chosen to mount it on was the ’77 GP machine OW35. It was given a new project code, OW35K, and work got under way. Development work had already been done for mounting the system on single-cylinder motocrossers, but this was the first time for a four-cylinder machine, and it brought a number of unique problems, like how to attach the cylinder to the crankcase and whether to make the four YPVS valves jointly operable,” says Mr. Taichi Ito, one of the engineer staff.

“The most common way to fasten the cylinder to the crankcase was to use stud bolts and nuts to bolt it down together with the cylinder head. However, due to the addition of the drum-shaped YPVS valves to the cylinders, a normal through-type stud bolt could not be used on the front side of the cylinder. So, at first we adopted a system where a flange was added to the front side or the cylinder for fastening, while the rear side was fastened in the usual method along with the cylinder head with stud bolts and nuts. But, the fact that the front and rear sides of the cylinders were fastened differently, thus creating imbalances in load, led to problems like cracking of the cylinders or crankcases. So, eventually we had to use a flange system on the rear side as well,” recalls Mr. Ito.

“What’s more, the addition of the YPVS valve caused greater heat distortion in the cylinders that led to problems like piston seizure, so we had to try a lot of new methods to alleviate this problem, like changing the shape to the piston cam model and the honing of the cylinder,” adds Mr. Ito. But these development efforts paid off, and eventually contributed to Roberts winning his first world title on the YZR500 in 1978. This returned the title to Yamaha after successive wins by Barry Sheene on his Suzuki in ’76 and ’77. As the YPVS continued to evolve, Roberts went on to win three successive titles.

Today, a wide range of two-stroke powered Yamaha products from production Enduro and motocross machines to production road racers, snowmobiles and personal watercraft mount the YPVS technology. Among these, Yamaha’s Wave Runner PWCs use the YPVS as a device to boost the effectiveness of the exhaust-cleaning catalyzer by functioning to control exhaust temperature. This technological know-how would play a vital roll in the YZR500s revolution after the OW35K.

In 1981, the year after Kenny Roberts won his third consecutive world title on the YZR500, the GP became the focus of attention for new reasons. That year, Yamaha introduced a square-four model YZR500 (OW54), while Suzuki introduced the RGG500 with a square-four with a level difference between the two front and two rear cylinders. Kawasaki rolled out its KR500 and Honda entered with the four-stroke NR500. The next year, Honda finally came in with the two-stroke, three-cylinder NS500. As it turned out, the winners in ’81 and ’82 were Suzuki’s Marco Lucchinelli and Franco Uncini.

Amid these developments, Yamaha introduced its last parallel four (OW53) and its first square-four (OW54) in 1981. In 1984 came the second-generation Yamaha square-four (OW60) and its first V4 engine model, the OW61. “Through 1980 we ran with the parallel fours, but in order to match the power performance of the rival square-fours, we began development of a V4 as our next-generation racer. There was a lot of risk involved in suddenly jumping in to the races with a V4, so we first developed the same kind of square-four as the competition and fed back used the race data gained with it to the V-4 development project,” recalls Mr. Ito. What proved to be the biggest problem with the V4 design, however, was the layout of the intake system.

The square-four model OW54 introduced in 1981 adopted a rotary-disc valve that definitely delivered more power than the conventional piston-valve type parallel four. However, the added weight of the engine affected the handling stability, which led to a number of problems. Eventually, the V4 engine OW61 model was the product of development efforts aimed primarily at solving these problems by reducing engine weight and reducing its width to one comparable to a 250cc engine.

Since a two-stroke engine has a separate crankcase for each cylinder, the width of a single-axis (shaft) V4 ends up being about the same with as a parallel four. However, adopting a two-axis design enabled a design with less right-left width. It also theoretically offered the advantage of easier voluntary adjustment of the ignition angle, but the problem became where to position the intake system. In other words, the question was where on a V-4 design could you position the intake system for the rotary disc that was normally positioned on the side (lateral) surface of the cylinder.

The key that would lead to the solution of this problem came from words muttered by one of the engineers in a development staff meeting. “One day, one of our engineers was mumbling to himself, ‘If only the disc could within the “V” bank between the cylinders.’ At that minute the whole picture became clear,” recalls Mr. Shiohara. This gave birth to a highly original concept of throwing out the side-mounted rotary disc with its inherently limited forward projection area, positioning the carburettors in the “V” of the block and having one rotary disc service two cylinders. Now the race was on to test a prototype and get it ready for use in actual competition. This led to the birth of the rear-surface rotary-disc valve intake system.